As the vertical farming industry continues to expand, growers are turning to Spiral Water’s Advanced Automated Self-cleaning Filters to treat, recycle and reuse their wastewater effectively and efficiently. This comes at a time when, according to an

Allied Market Research Report, “the [global] vertical farming market size was valued at $3.24 billion in 2020, and is projected to reach $24.11 billion by 2030, registering a CAGR of 22.9%.”

What is vertical farming?

Vertical farming is designed to optimize crop yields while minimizing space and resource requirements such as water and energy. Crops are grown in vertically stacked layers (thus optimizing vertical space), often in hydroponic systems, while using artificial light sources (frequently powered by renewable energy) and precise nutrient solutions.

This technique allows for the cultivation of crops in a controlled environment, regardless of external weather conditions or the availability of arable land. The environment is optimized for the plants’ growth and health, with parameters such as temperature, humidity, and carbon dioxide levels carefully monitored and adjusted as needed.

What are its benefits?

Vertical farming represents an exciting and growing development in agriculture. Shifting the production of crops from traditional, land-consuming outdoor farms translates into a greatly reduced land footprint as well as considerably less of an environmental impact. With indoor vertical farming, crops can be grown throughout the year, even in urban settings. Vertical farming also consumes far less water than traditional agriculture (it’s estimated that agriculture currently accounts for 70-80% of freshwater withdrawals globally), and the water can be recycled and reused. It can also reduce pesticide use.

In addition, vertical farming can also provide a way to grow fresh produce closer to the point of consumption, minimizing the need to haul it over long distances. This reduces the cost of transportation, lowers fossil fuel consumption, and reduces emissions. Another benefit is that the produce is fresher when it reaches the consumer.

How are Spiral Water filters used?

In many cases, vertical farms use advanced irrigation systems that are designed to be highly efficient and minimize water waste. Drip irrigation, hydroponics and aeroponics are effective ways to deliver water to the plants while preventing waste due to runoff or evaporation.

In many cases, vertical farms use advanced irrigation systems that are designed to be highly efficient and minimize water waste. Drip irrigation, hydroponics and aeroponics are effective ways to deliver water to the plants while preventing waste due to runoff or evaporation.

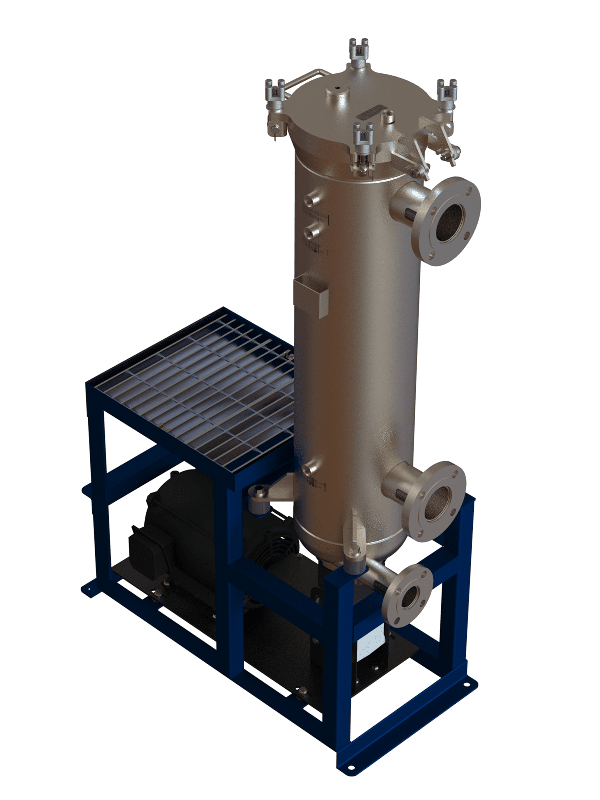

Spiral Water filters provide a key component in any water recovery and reuse approach, and they are very wellsuited to the requirements of vertical farming. In the case of vertical farming, nutrient-rich water being used in hydroponic drips can pick up particles and other solid debris during this process. Spiral Water filters can ensure that water is free of these contaminants before being reintroduced into the system so that it does not foul nozzles or disturb the lines. Our filters can also be used to treat wastewater bound for discharge and ensure that it complies with strict community discharge limits.

Our next-generation automatic self-cleaning filters are widely used for industrial and organic wastewater treatment, pretreatment for microfiltration, ultrafiltration and reverse osmosis, water recycling and reuse across a variety of industries. Engineered with our patented high solids filtration and concentration technologies, they can be used as a pre-filter, primary filter or for reclamation from existing filter backwash of centrifuge overflow. They are known for their ability to handle wastewater TSS removal and to process bulk solids removal up to 15,000 mg/l TSS (15% by volume), providing continuous 15 to 1500 micron filtration. (Removal of TSS typically also removes a percentage of BOD and COD.) In addition, our proprietary one-pass filtration process eliminates backwash of cross flow, thus conserving water, increasing uptime, and reducing Capex.

We invite you to learn more about our filters and their application in vertical farming. Contact us by email or by calling us at 732-629-7553.