The aquaculture industry has become increasingly important in meeting the growing global demand for seafood, as wild fisheries face challenges such as overfishing, habitat destruction, the effects of climate change, and declining fish stocks.

Enabling aquatic organisms to be raised in controlled environments, aquaculture can provide a more reliable, sustainable and efficient means of seafood production.

While the demands for cultivating these species vary, the need for effective treatment of water and wastewater involved in their production is universal, with filtration being vital to the process.

An overview

Filtration is used for numerous steps in aquaculture. They include:

- Filtering intake water to remove debris and natural impurities such as high total suspended solids (TSS). Because intake water often comes from various untreated sources, such as rivers, lakes, streams, ponds and oceans (often referred to as “natural water”), filtration to remove these contaminants is an important first step.

- Maintaining water quality. In aquaculture systems, fish and other aquatic organisms excrete waste from uneaten feed, feces, and metabolic byproducts that, if allowed to accumulate, can lead to the deterioration of water quality. In turn, this can result in nutrient imbalances and increased risks of disease. Filtration helps remove suspended solids, organic matter, and other impurities from the water, helping to maintain optimal water quality parameters and ensure a healthy environment for the aquaculture species.

Treating nutrient-rich wastewater to make it suitable for reuse. Efficient filtration practices help minimize water waste and reduce the overall environmental impact of aquaculture operations. By reusing and recycling water through proper filtration, aquaculture becomes more sustainable and environmentally responsible.

An ideal solution

Spiral Water’s advanced automatic high solids separation and concentration technology is engineered to solve the specific challenges of filtering ultra-high and variable total suspended solids (15,000 mg/I) from water and wastewater streams. No other automatic self-cleaning filter can perform at this level.

- That’s only one of several salient design features that make our filters stand apart from the rest. Our filter systems:

- Provide trouble-free operation in higher TSS solids loading of 10,000 ppm+. Standard backwash filters can only handle TSS less than 500 ppm.

- Manage variable TSS automatically.

- Offer continuous filtration plus solids concentration and solids conditioning for feedstocks and reuse of nutrient-rich water – efficiently removing particles, debris, and organic matter. This helps maintain a stable and healthy aquatic environment for the farmed species.

- Provide continuous filtrate – 99%, producing less water to waste and making our filters a smart component in any water recovery soluti

- Operate effortlessly at low system pressures as low as 10 psig – no pulsing. Retrofits require no additional pump modifications.

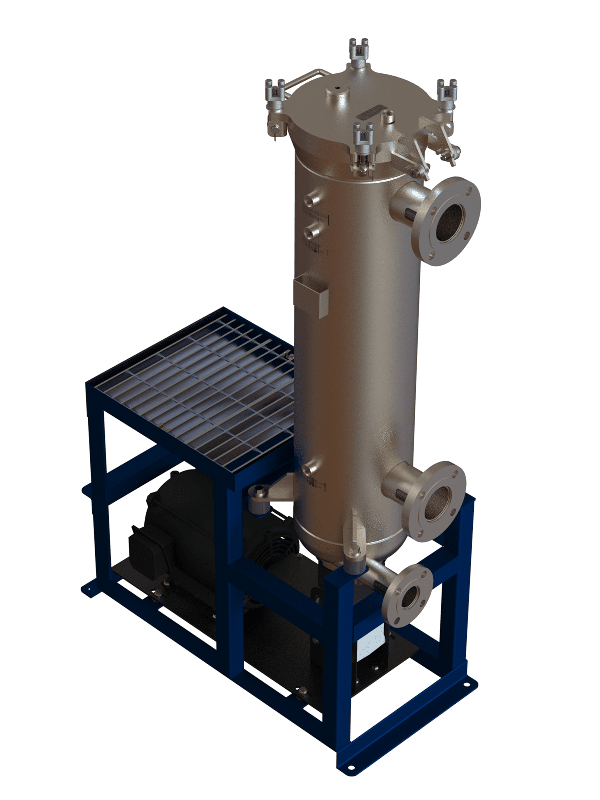

- Feature industry’s smallest footprint. Our filters are simple to maintain, modular and scalable.

- Are equipped with smart controls that allow reliable automated filtration from 15 to 1000 micron.

In addition, our self-cleaning filters help reduce labor and maintenance and they are designed for longevity, durability and reliability – crucial in aquaculture systems where uninterrupted filtration is critical.

Spiral Water’s Model 850PVC-SMS is ideal for aquaculture applications. All materials are suitable for use in oceans, ponds, and brackish water environments. The are available in 316 stainless steel, PVC and CPVC housings.

For more information about Spiral Water’s technology and products, click here.