In April, Spiral Water attended the New Jersey Food Processors Association show, where our exhibition booth was welcomed and well attended.

The show offered a productive opportunity for Spiral Water to showcase our filtration technology and systems and our extensive experience working with companies in the food processing industry. Of course, water is indispensable in the food processing industry. It’s well known that this industry is one of the largest consumers of water globally, since significant amounts of water are required for operations that vary from washing raw materials to cleaning equipment, and use as an ingredient in food products.

Here are some thoughts about how Spiral Water’s products can increase productivity, help lower costs, and also help enable food processing companies to address other challenges.

- Managing costs associated with water. The cost of water can be substantial. Costs include not only the price of the water itself but also expenses related to water treatment, heating, wastewater disposal, and labor and energy costs. Additionally, fluctuations in water prices and availability can impact production costs and profitability.

- To mitigate costs and reduce environmental impact, many food processing companies are implementing water conservation and reuse and recycling measures. Additionally, technological advancements such as water-saving equipment and automated control systems that reduce labor costs and minimize downtime help in improving overall efficiency. Spiral Water’s technology can play an important role in helping to improve productivity and reduce OpEx.

- Investing in the right technology can pay off in the long run. Despite upfront investments in infrastructure and technology, the long-term benefits, including cost savings, regulatory compliance, and sustainability, often outweigh the initial costs. Such is the case with Spiral Water’s products and engineered systems.

- Keeping pace with technological advancements. It is crucial for food processors to continue to improve efficiency, enhance product quality, and meet growing consumer demands. Food processing companies are increasingly adopting smart manufacturing technologies and automation to improve efficiency, reduce costs, and ensure food safety. This includes the use of robotics, sensors, and data analytics throughout the production process. Contact us to learn how Spiral Water systems can be integrated into smart manufacturing systems.

- Maximizing environmental sustainability. Increasing consumer awareness and regulatory scrutiny have heightened the importance of environmental sustainability in food processing operations. Spiral Water products and systems can help food processors minimize their environmental footprint by reducing energy consumption, water usage, and waste generation.

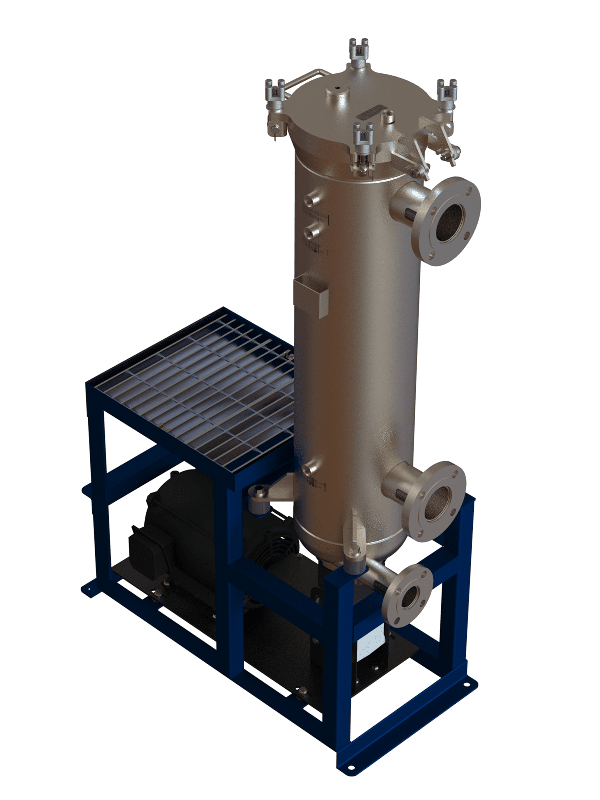

Food and beverage processors across the country trust Spiral Water Technologies’ products to filter wastewater effectively and cost-efficiently. Our automatic filtration products efficiently remove Total Suspended Solids (TSS) and Biological Oxygen Demand (BOD), which indicate the presence of large particulates and microorganisms, respectively. They effectively clean the water to be used in food production. They also treat wastewater generated in the food and beverage production process, so that the wastewater is suitable for reuse or removal. Click here to find out more.