There are many challenges involved with wastewater treatment. Businesses must not only operate efficiently but comply with federal and state regulations while remaining cost-effective. This can become difficult in industries that handle variable total suspended solids (TSS) and high solids loading. Without proper filtration equipment, high TSS levels can cause blockages, fouling, and costly unplanned downtime.

Two common filtration solutions are backwash filters and self-cleaning automatic filters. Backwash filters are suitable for less demanding applications; however, they struggle to manage TSS levels above 200 ppm. In contrast, Spiral Water’s proprietary mechanical self-cleaning filters can handle TSS levels of 15,000 ppm. In this comparative study, we’ll discuss the performance features of both filter designs to help you make a better-informed purchase decision.

Understanding Self-Cleaning Automatic Filters and Backwash Filters

Before determining the best filter for your needs, it’s important to understand how self-cleaning automatic filters and backwash filters work, and how Spiral Water filters differ.

What Are Self-Cleaning Automatic Filters?

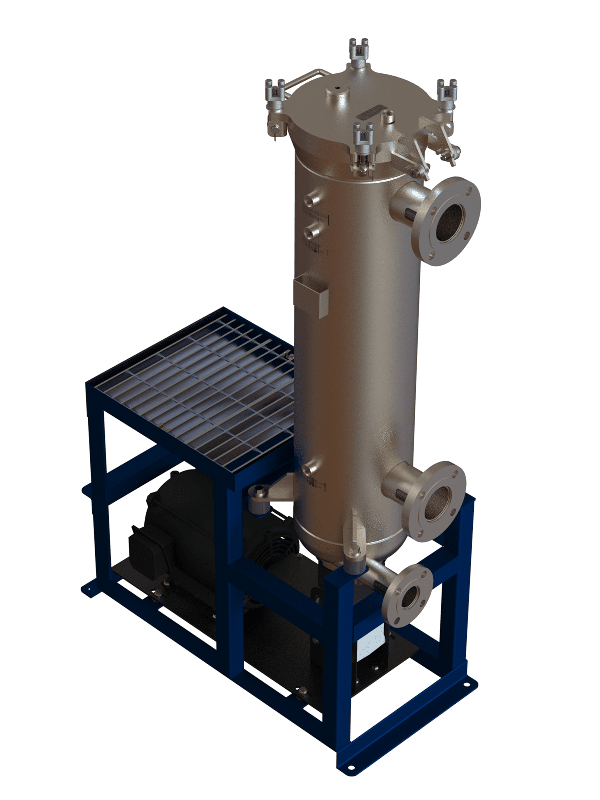

Self-cleaning automatic filters function by automatically separating suspended solids from fluids without the need for total system shutdowns. Spiral Water’s patented mechanical cleaning distributor operates continuously to thoroughly scrape solids off the filter’s surface. This helps to prevent clogs and achieve improved performance, even under high TSS conditions.

How Spiral Water’s Technology Differs

Compared to standard backwash filters that can handle up to 200 ppm of TSS, our filters manage ultra-high and variable TSS up to 15,000 ppm while concentrating solids for low-volume discharge. The robust cleaning mechanism ensures reliable operation, even within the extreme conditions that would cause other filters to fail. Installing our backwash filtration systems results in increased equipment protection and greater uptime of compressors, bearings, equipment, and systems.

What Are Backwash Filters?

Backwash filters are large, tank-style products that use reverse water flow to remove accumulated solids from the filter media. However, some major drawbacks of these systems are that they require frequent system downtime and use a substantial amount of water for backwashing, which can hinder water conservation efforts. Backwash filters can typically only manage TSS levels below 200 ppm, making them less suitable for high-solids environments.

Comparative Analysis: Self-Cleaning Automatic Filters vs. Backwash Filters

Self-cleaning automatic filters from Spiral Water and traditional backwash filters differ in their filtration capacity, maintenance requirements, scalability, and more. Below, we’ll compare these differences.

Filtration Capacity

Spiral Water’s self-cleaning automatic filters handle up to 15,000 ppm TSS levels, a staggering difference compared to backwash filters which manage under 200 ppm. This makes our filters far more suitable for demanding applications that experience high or seasonally erratic levels of suspended solids.

Maintenance Requirements

Spiral Water filters need minimal maintenance due to their automatic cleaning system, which continuously removes debris without having to stop operations. In contrast, backwash filters need ongoing intervention to perform manual cleaning, which increases operational downtime and labor costs.

Footprint and Scalability

Backwash filters have a large design that features sizable tanks and pumps. This makes them unsuitable for environments where space is limited. Spiral Water filters, on the other hand, have been designed with an extremely small footprint. Not only are they ideal for facilities with limited space, but their modular design means they are easily scalable to meet application-specific needs.

Water Waste and Efficiency

Water conservation is an important issue for many industries. While backwash filters require significant volumes of water to reverse flow and remove solids, our proprietary self-cleaning filters use minimal water during the purge cycle.

SWT Filter Systems deliver continuous filtration up to 99% and produce significantly less waste water, making them a great option for water recovery solutions. Additionally, they operate optimally at system pressures as low as 10 psig, and retrofitting requires no additional pump modifications.

Choose Spiral Water for Your Filtration Needs

If you need a filtration solution capable of handling variable TSS levels or high solids loading, Spiral Water’s innovative self-cleaning automatic filters deliver unrivaled results over conventional backwash filters. Our patented internal cleaning mechanism creates a highly effective hydrodynamic agitation to keep your filters clean and maintain constant differential pressure across the entire filter. This ensures your filters remain online compared to other options that would overload and fail.

Choose our solutions to better prevent failure and minimize unplanned downtime. To learn more about how our products can improve your system performance, contact our team today.