Companies, consumers, and industries are turning toward sustainable energy sources for operations. Renewable natural gas (RNG), also known as biogas, is a renewable energy source derived from decomposing organic matter. As renewable natural gas/biogas develops from anaerobically decomposing material, facilities can collect and refine that gas for use as an energy source. Because it relies on organic matter like farm animal manure and other waste byproducts, RNG is plentiful, renewable, and much more eco-friendly than other energy sources. However, it does rely on the right processing tools, including a high-performance water filtration system.

See Our Renewable Natural Biogas Industry Flyer

Importance of Water Filtration in Renewable Natural Gas & Biogas Applications

Water filtration plays a significant role in RNG production. The process involves turning off-gassing products and decomposing material into a useful energy product, which requires filtration. Specifically, it requires a high degree of filtration to maintain a consistent quality of gas and to protect the processing equipment from byproducts in unfiltered material. By incorporating a water filtration step in the production process, companies can build a more scalable, repeatable process.

Main Areas of Renewable Natural Gas/Biogas Filtration Applications for Spiral Water

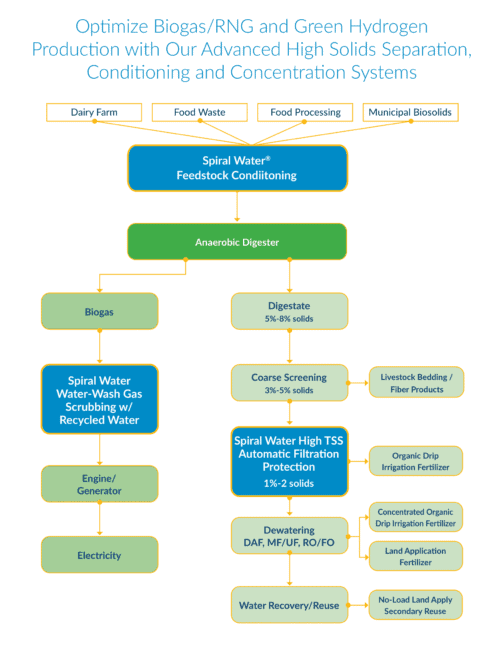

Biogas sources need to be purified before they can be turned into renewable natural gas. Spiral Water’s products are used in the prefiltration process for many biogas applications. Treatment processes at the beginning of this cycle include:

Gas Scrubbing

Water gas scrubbers are highly effective at removing a wide range of impurities from gas streams. They are easily scalable, depending on the size of your plant and because they use water (a non-toxic solvent) it is an environmentally friendly process. Gas scrubbers play a key role in the practical implementation of biogas and green hydrogen technologies by removing impurities and cooling the gas stream.

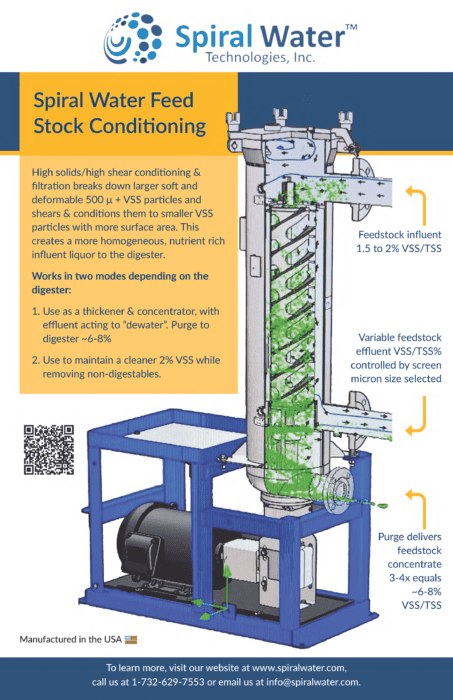

Feedstock Conditioning

Spiral Water’s systems are placed before anaerobic digesters to condition feedstock and remove as much contaminant as possible before it goes through the next stage in the filtration process. Through different case studies, our systems have shown a 10-30% increase in methane production while also reducing OpEx.

Digestate Processing

After feedstock conditioning is complete, digestate needs to be removed. Our automatic self-cleaning filters remove inorganic non-digestible solids and homogenizing digestible solids from the wastewater stream. This helps increase gas production and reduce operating.

Benefits of Water Filtration in Renewable Natural Gas & Biogas Applications

Filtration is a critical component of RNG production and processing. Raw biogas includes several impurities that can be removed through water filtration systems, and those impurities must be removed to produce a useful energy source. Consider these specific benefits of adding on-site water filtration capabilities to your RNG production facility.

Improved Quality of Renewable Natural Gas & Biogas

The quality of RNG relies on multiple different factors, including its purity. At the beginning of the production stages, biogas has moisture, contaminants, and carbon dioxide—all elements that must be eliminated before the final stages of production. The right water filtration system can improve the quality of the RNG by:

- Separating solid waste and impurities before the fluid enters a digester unit; these impurities include the plastics, sand, and stone that would otherwise remain in the product

- Increasing the portion of methane in the RNG produced by digester units by 10-30%

Prevention of Equipment Damage

Contaminants do more than lessen RNG quality. It can also pose a hazard to your equipment. Unfiltered products can lead to hydrate formation on internal surfaces and increase the risk of corrosion. By filtering the product earlier in the processing stage, you protect your equipment so the components last longer, need less maintenance, and won’t need to be replaced as frequently.

Save Time and Money

Employing a water filtration system streamlines the process. You can save money because:

- There are fewer maintenance and labor costs compared to using a centrifuge.

- You can access rebates, green energy incentives, and carbon credits.

- Water filtration replaces the need for many costly chemicals.

- You use less energy than DAF with electro-flotation.

Your operation can also save time by lowering reliance on labor and reducing dwell time.

Environmental Benefits

RNG offers several environmental benefits, especially because it reduces reliance on other, less eco-friendly energy sources such as fossil fuels. Anaerobic Digestion (AD) systems can collect and recover biogenic methane, reducing overall emissions and preserving the air and water quality. It can even help local economies. By using water filtration systems before introducing matter to the digester, you can filter out and separate impurities to comply with environmental standards. The water itself can be purified to reduce pressure on wastewater systems.

Water Conservation

After anaerobic digestion is complete, processors are left with both biogas and digestate, a nutrient-rich byproduct. By filtering out water from the digestate, you can produce a compact, nutrient-rich fertilizer, with a consistent concentration based on how much water is removed. The water can be reused, and the fertilizer can be sold to organic markets.

Renewable Natural Gas Water Filtration Systems by Spiral Water

Renewable natural gas is a rich energy source. With the right water filtration system on hand, you can separate our solid particles before introducing the waste products to an agitator. Afterward, you can further extract value by separating filtered water from the digestate. At Spiral Water, we design and develop water filtration systems built to help you harness the full power of renewable natural gas. Contact us today to learn more.