Managing high solids loading is an important aspect of water and wastewater treatment across numerous industrial processes. Industries such as pharmaceuticals, power generation, and food and beverage processing often deal with high levels of total suspended solids (TSS); fats, oils, and greases (FOG); and biological oxygen demand (BOD) in wastewater, backwash water, or process water. These contaminants can wreak havoc on traditional filtration systems, which can lead to fouling, blockages, and costly unplanned downtime.

Addressing high solids loading is also crucial for industrial processes that discharge wastewater to downstream waters or treatment facilities. Failing to effectively remove solids can result in non-compliance with local, state, and federal regulations, which can lead to expensive fines and surcharges. Additionally, with an increasing focus on water conservation, many industries are trying to reuse as much water as possible by recirculating treated wastewater back into their processes. Conventional filtration techniques like multimedia or sand struggle to purify high-solids wastewater to a level suitable for discharge or reuse.

Rather than relying on outdated bag, cartridge, or media filters, organizations can optimize their processes by using advanced self-cleaning filters from Spiral Water Technologies (SWT). Learn more about how making the switch to modern filtration systems can benefit your operations below.

Viability of Self-Cleaning Filter Technology

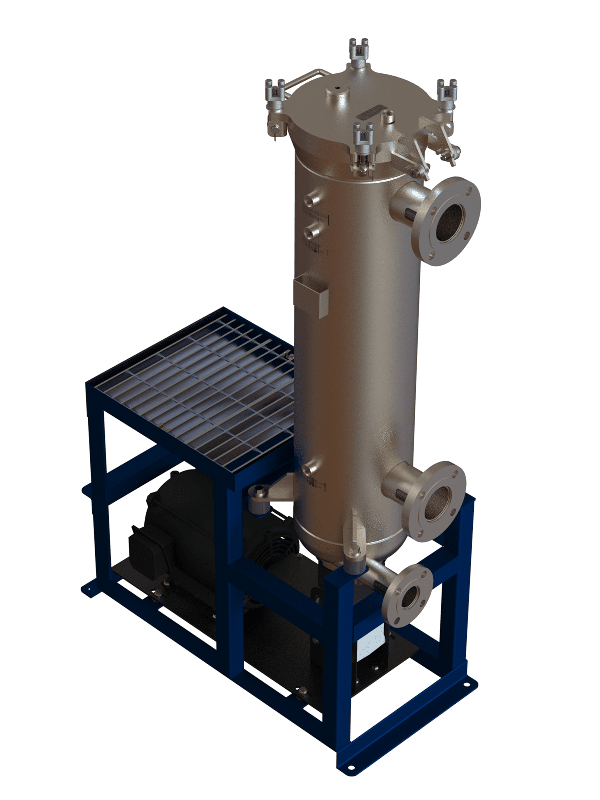

Automatic self-cleaning filters offer a cost-effective and viable alternative for treating particulate-heavy processes and wastewater. While conventional filtration technology has been around for decades, it has recently been proven unable to manage high solids loading for extended periods without blinding off. Our liquid/solid separator and automatic self-cleaning filters address this issue by being able to remove variable and ultra-high TSS while simultaneously concentrating solids for low-volume discharge.

For applications involving variable TSS process streams, our solutions offer less downtime due to natural upset conditions. End users who install Spiral Water’s filters often see enhanced protection and uptime of their compressors, bearings, systems, and equipment.

How it Works

Unlike standard backwash filters, Spiral Water filters feature a mechanical cleaning system. Our patented distributer/cleaning assembly spins off tip vortices, resulting in hydrodynamic agitation that more effectively keeps filters clean while maintaining a constant differential pressure (DP). DP builds up with backwash filters, resulting in increased energy waste.

Spiral Water filtration and concentration units contain motor-driven, spiral-shaped brushes that continuously clean collected contaminants from within the filter element. Each unit can filter up to 100 gallons per minute at 15 to 25 microns, with higher flow rates achievable by combining multiple units. Solids build up at the bottom of the filter housing before being expelled through an automatic purge valve. An agitator within the purge chamber keeps any collected and concentrated solids in a fluid state to prevent caking and clogging.

SWT systems don’t require high inlet pressures to operate and are rated for up to 150 psi. They can also perform reliably at low differential pressures of less than 2 psi. Since our filter systems do not use backwash to clean the filter screen, they can concentrate solids to a high degree. Collected and concentrated solids can either be purged as a slurry or sold.

Compared to bag, cartridge, and media filters, Spiral Water’s advanced filtration technology offers significant advantages. When implemented into existing process solutions, operators can achieve filtration results (<25 microns) not possible with conventional methods. This not only supports water reuse objectives but helps to reduce costs and boost efficiency.

What Makes SWT Different

Spiral Water’s advanced self-cleaning filters provide security for systems affected by high solids loading and variable TSS. Compared to standard self-cleaning filters that are only capable of handling TSS up to 500 ppm, our advanced self-cleaning filters can manage TSS higher than 5,000 ppm. Our patented internal cleaning mechanism keeps filters operating where other options would overload and fail.

Automatic self-cleaning filters from Spiral Water provide numerous beneficial features, including:

- Offers trouble-free operation in high TSS solids loading of more than 10,000 ppm

- Automatically manages variable TSS (standard backwash filters can only handle TSS less than 500 ppm)

- Provides filtration, solids concentration, and solids conditioning for feedstocks

- Provides continuous filtration up to 99%, resulting in less water to waste

- Operates effortlessly at low system pressures with no pulsing

- Offers the industry’s smallest footprint while being modular, scalable, and easy to maintain

- Includes smart controls for reliable automated filtration from 15 to 1,000 microns

Upgrade Your Water Filtration System With Spiral Water Technologies

If you’re looking to reduce water consumption, support reuse initiatives, or protect downstream equipment, consider advanced automatic self-cleaning filters from Spiral Water. Our systems operate more efficiently and reliably than conventional filter options while being able to handle much higher levels of TSS. Our products have also been proven to be effective in new market applications such as hemp separation, biogas pre-digesters for improved gas production, and more.

For more information about our innovative self-cleaning filtration solutions, contact us today.