Microplastic filtration serves an important function in various markets, including plastics recycling, wastewater treatment, biogas, and more. Microplastics are very small pieces of plastic that come from numerous sources such as the breakdown of plastic litter, microbeads used in cosmetics, microfibers from textiles, and industrial waste. Micropollutants represent a broader category of small-scale chemical pollutants from a wide range of sources including pharmaceuticals, pesticides, personal care products, chemical compounds, and heavy metals. While both can harm the environment and have adverse effects on health, microplastics are often more persistent and physically invasive, while micropollutants can be chemically reactive and toxic.

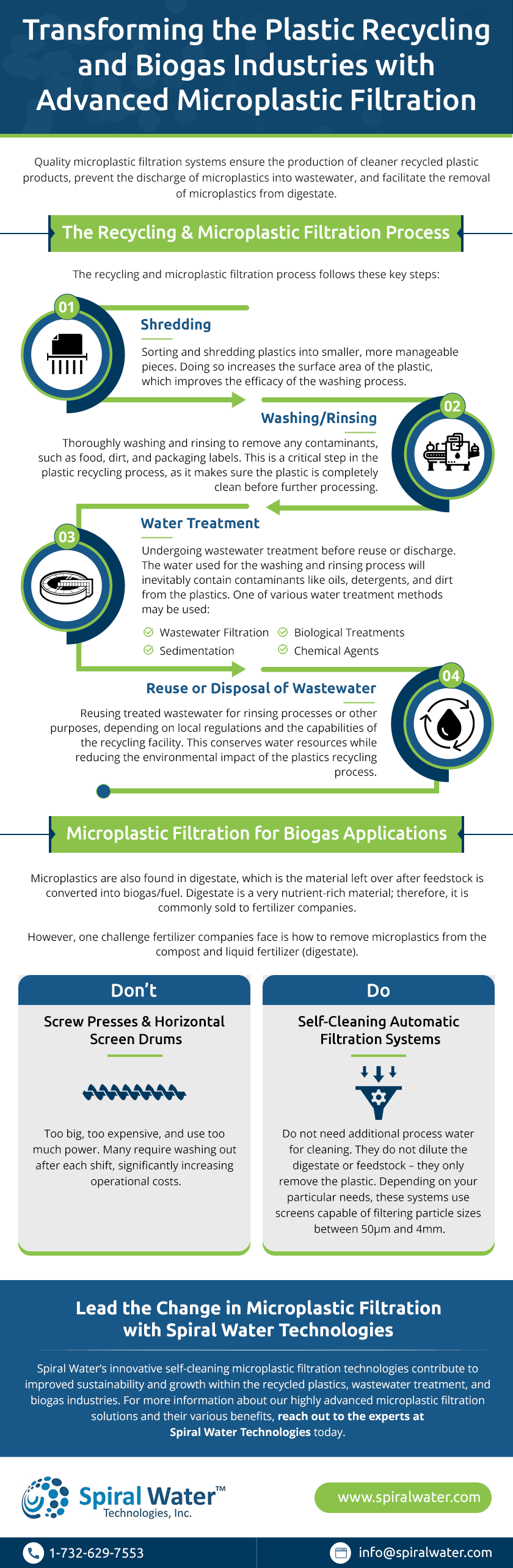

Within these applications, quality microplastic filtration systems ensure the production of cleaner recycled plastic products, prevent the discharge of microplastics into wastewater, and facilitate the removal of microplastics from digestate.

Spiral Water Technologies is at the forefront of advanced microplastic water filter solutions that contribute to more effective and efficient filtration processes. The global impact of our innovative products extends to preserving water resources, protecting environmental health, and boosting sustainability within a range of critical industries.

The Recycling & Microplastic Filtration Process

The recycling and microplastic filtration process follows these key steps:

Shredding

The recycling process begins by sorting and shredding plastics into smaller, more manageable pieces. Doing so increases the surface area of the plastic, which improves the efficacy of the washing process.

Washing/Rinsing

The shredded plastics are then thoroughly washed and rinsed to remove any contaminants, such as food, dirt, and packaging labels. Washing typically requires water and, in some cases, detergents to remove stubborn residues that may still be present on the plastic. This is a critical step in the plastic recycling process, as it makes sure the plastic is completely clean before further processing.

Water Treatment

The water used for the washing and rinsing process will inevitably contain contaminants like oils, detergents, and dirt from the plastics. This contaminated water, known as wastewater, must undergo treatment prior to reuse or discharge. Depending on the type and amount of contaminants present, one of various water treatment methods may be used:

- Wastewater Filtration

- Sedimentation

- Biological Treatments

- Chemical Agents

Spiral Water’s patented high solids filtration technology is ideal for process bulk solids removal and TSS/BOD removal up to 15,000 mg, offering continuous 15 to 1,500 micron filtration. Our innovative self-cleaning mechanical filters provide proven capabilities as well as valuable dewatering and waste management benefits.

Reuse or Disposal of Wastewater

Treated wastewater may then be reused for rinsing processes or other purposes, depending on local regulations and the capabilities of the recycling facility. If it’s not being reused, it can be discharged into the environment or municipal sewage system. Properly disposing of or reusing wastewater helps to conserve water resources while reducing the environmental impact of the plastics recycling process.

The Market

The recycled plastics market was valued at nearly $70 billion in 2023 and is predicted to grow to $120 billion by 2030, at a compound annual growth rate (CAGR) of 8.1%. The increased use of recycled plastics in food and beverage packaging, automotive, electronics/electrical, packaging, and various other industries directly contributes to the heightened demand for these materials. As the global market for plastic recycling continues to grow, so too does the need for advanced microplastic water filters.

Wastewater Treatment for Recycling Applications

Microplastic water filters from Spiral Water Technologies play a critical role in the overall systems and processes that remove waste for water recycling applications. We design all of our microplastic filtration products for maximum speed and efficiency.

Our wastewater treatment solutions employ a filter press to remove solids from wastewater effectively. This aids in the dewatering process and allows for the return of clean water. Spiral Water’s fully automated, proprietary dewatering methods and ultra-high pressure filtration eliminate the need for settling ponds and reduce reliance on flocculants. Additionally, our products decrease manpower requirements for a more efficient and cost-effective operation.

Microplastic Filtration for Biogas Applications

Microplastics are also found in digestate, which is the material left over after feedstock is converted into biogas/fuel. Digestate is a very nutrient-rich material; therefore, it is commonly sold to fertilizer companies to be used as organic drip irrigation fertilizer, concentrated organic drip irrigation fertilizer, and land application fertilizer.

However, one challenge fertilizer companies face is how to remove microplastics from the compost and liquid fertilizer (digestate). While other equipment is available in today’s market, they are all non-pressurized solutions. Most digestate processors prefer pressurized systems such as our Model T1000 filters.

Filtration solutions like screw presses and horizontal screen drums that are open to the atmosphere are too big, too expensive, and use too much power. Additionally, horizontal screens/housings can create dry formations at the bottom of the screen section that require washing out after each shift, significantly increasing operational costs.

Our patented self-cleaning microplastic filtration systems do not need additional process water for cleaning. This means our systems do not dilute the digestate or feedstock – they only remove the plastic. Depending on your particular needs, these systems use screens capable of filtering particle sizes between 50µm and 4mm.

Lead the Change in Microplastic Filtration with Spiral Water Technologies

Spiral Water’s innovative microplastic filtration technologies contribute to improved sustainability and growth within the recycled plastics, wastewater treatment, and biogas industries. For more information about our highly advanced microplastic filtration solutions and their various benefits, reach out to the experts at Spiral Water Technologies today.